Hot Selling for Concrete Plastic Formwork - 120#steel formwork – Zhongming

Hot Selling for Concrete Plastic Formwork - 120#steel formwork – Zhongming Detail:

Product Introduction

Luowen 120 Steel Frame Formwork System is mainly made up of steel frame, plywood panel,scaffold bracket,coupler,compensation waler,tie rod,lifting hookformwork, steel clamp and pull-push prop, etc

1. The steel frame formwork is 18mm thickness plywood covered with hollow steel.

2. The frame is highly strengthened, and the wall formwork can bear lateral pressure 60KN/m2 while the column formwork can bear 80 KN/m2.

3. As a standardized system, it is flexible to assemble, wood batten can be filed to satisfy the need of non-standard size.

4. The adjustable steel clamp is convenient to use ,and can hold tightly.

5. There is a prizing part designed in the corner ,which can help to position and remove formwork easily.

6. The plywood is screwed on from the back when connecting frame and plywood ,so the surface of the finished concrete is perfect.

7. The formwork series are a complete system with a full set of accessories ,and can be set up flexibly according to project demand.

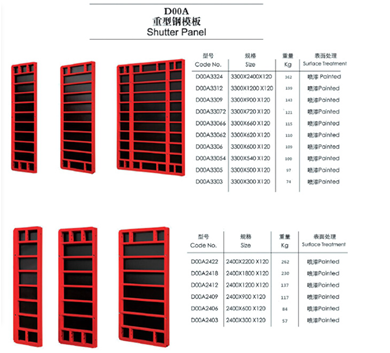

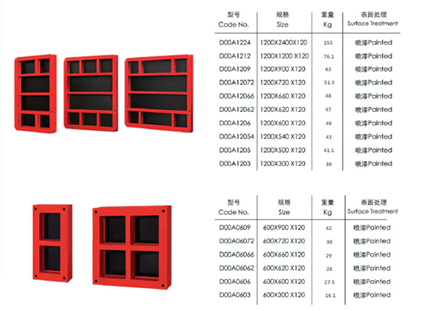

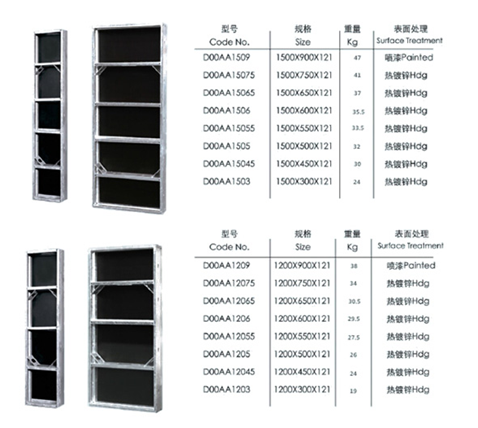

Product Details

1.plywood thickness:18mm

2.weight:40-60kg/m2.

3.Surface treatment:paint spraying

4.lateral pressure:60-80 KN/m2.

Advantages:

1.Steel forms are durable and stronger.

2.Provides uniform and smooth surface finish to the structure.

3.Great reusability.

4.Easy to fix the formwork and also easy to dismantle.

1.120 Universal Panel Formwork System consists of steel frame, plywood panel, push-pull prop, scaffold bracket, alignment coupler, compensation waler, tie rod, lifting hook, etc.

2.Plywood panels could be Wisa -form or homemade plywood with high quality. The steel frames therein are made of special cold roll-forming steel, no waler, with the weight of 64kg/m2 so as to easy to carry.

3.The connection between panels adopts alignment coupler rather than those of bolts or ‘‘U’’ clips which are low efficient and complicated so that it greatly improves the working efficiency.

4.Compensation waler strengthens its integrate rigidity at panel connection location.

5.High turnover, easy operation, reasonable load, convenient storage and transportation, low aggregate costs.

6.120 Universal Panel Formwork System completely makes the formwork implementation, mechanization, and standardization come true, in other words, an ordinary tool, for example a hammer, is nough to finish the erection work efficiently.

2. 120 Light-duty Panel

Product detail pictures:

Related Product Guide:

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we're hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for Hot Selling for Concrete Plastic Formwork - 120#steel formwork – Zhongming, The product will supply to all over the world, such as: Nicaragua, Malawi, Honduras, Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we are working hard to give you the wholehearted service and willing to give you the most competitive price in the market

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.